We offer fabrication services for kitchen countertops, bathroom vanities for commercial and residential projects.

- We are well-known as one of the leading quartz slab producer and vanity and countertop supplier in Turkey.

- Our commitment is to provide our customers quartz countertops and vanity tops as highest quality.

- We committed to 100% customer satisfaction.

- All our products made by our slabs produced in Turkey.

- Our price is surely competitive.

- Delivery on Time

- For your large and small demands, welcome…Our large production capacity is ready to supply all of your demands.

KEY STRENGTHS AND CAPABILITIES

PrimeCore is a reliable source of high quality quartz products due to its 2 overseas factories located in Turkey.

Our dedicated and experienced professional team is the key ingredient of our success. At PrimeCore, we are committed to consistency of quality and completing the job on time at exceptional value to our clients.

PrimeCore specializes in jobs involving condominiums, hotels, multi-family housing projects, commercial office buildings, and restaurants.

Whether you are remodeling or building a new home, PrimeCore has variety selection of natural quartz for your choice. Our experienced craftsmanship and expert fabrication capabilities, distinguishes us as a supplier that is committed to quality.

- We offer manufacturing slab and fabrication services for custom kitchen countertops, bathroom vanities, fireplaces, and more.

- At Sadestone, quality and customer service is our top priority.

- We work with you each step of the way from project details through to the finished installation.

- We have different countertop surface options, color choices and envision how the backsplash, edge profile and countertop selection all fit together in any given project.

- We are always researching to improve quality of product, faster delivery and new products to meet higher demand of clients. We hope to have a long term business and relationship with clients with mutual profit and belief.

- No matter how custom or difficult your project is, if it quartz , we make it.

STONE FABRICATION

The polished quartz countertop that you have in your kitchen or bathroom undergoes an exceptional process of stone fabrication to make the finished product. It is remarkable just how much occurs during this process and how important it is to getting the most from your countertop for years to come.

The quartz fabrication process is done by a professional stone fabricator, which is a very experienced person. In most cases, we manufacture quartz slabs and also specializes in stone fabrication and everything can be done at our shop prior to being delivered to your job-site. This ensures our customers the convenience that one-stop shopping can lead to having more control over the entire process.

Firstly, we inspect the slabs before fabrication. Quartz is an engineered stone which is made by natural raw materials often contains characteristics indigenous to that particular material, similar to how individuals may be born with birthmarks. Some of these characteristics include black spots, pits, dry seams, polyester resin fill and natural directional veining, quartz conglomerates (knots). Mostly, these marks make the quartz slabs unique and beautiful. But sometimes customer may find certain characteristics unacceptable and the stone fabricator have to work to avoid those during fabrication process. The customer will be enjoying this quartz countertop in their home for years to come, it is critical to review the slab(s) to achieve the best possible outcome.

Before the templating, a final inspection is made of the slab, identifying any areas unacceptable to the customer, or areas that are more severe than the normal characteristics described above. The experienced fabricator marks those areas and works to avoid those during templating, while balancing the effort to minimize waste and therefore cost.

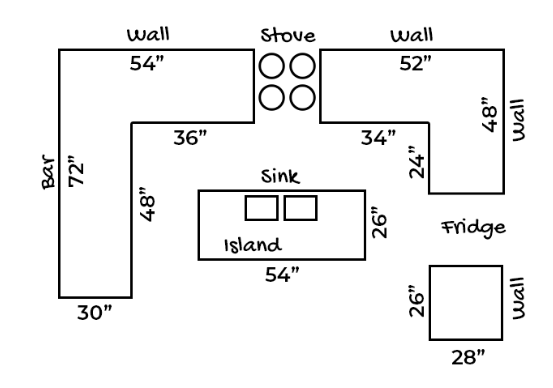

TEMPLATE LAYOUT

After slab inspection, it is then laid out and templates are put on the stone to ensure the best appearance of vein look. The templates are also used to ensure appropriate flow for the various countertops in your layout.

This is where an experienced fabricator is key, it is a mix of experience and artistry.

CUTTING THE SLAB

The quartz slab is cut using either a water jet or a bridge saw. This more specialized tool can be programmed with the parts you need to cut and determines where to use the water jet and where to use the saw, achieving higher productivity and quality.

The bridge saw cuts with a diamond blade at a speed rate of approximately 84 inches per minute. The water jet cuts with high pressure water with garnet particulate suspended in the water at a speed rate of 12 inches per minute. In addition to increase productivity, the bridge saw cuts just straight lines, where the water jet can cut circles, radiuses, or any intricate patterns.

After the pieces are cut from the whole slab, they are forwarded to a CNC router. On the CNC router, sink holes are cut and the stone countertop pieces are then fabricated.

FABRICATING

In this process of quartz fabrication, the cutouts for cooktop, sink or faucets holes are all made. The first step is cutting the stone for its final size. Then, the CNC router is programmed to know the size of the slab on the table. It can be put multiple pieces of quartz on the work-table together. CNC router is then programmed where the quartz pieces are located and what to do to each of these pieces. Quartz materials require the CNC router to move very slowly. In order to achieve the most accurate result, it is needed a specialized operator.

After the holes are cut in the quartz slab, the edge is eased and polished by the edge polishing machine just before piece is taken to final polish. There are a variety of edge profiles to choose from, but edge machine can produce any edge you select.

STRENGTHENING THE STONE

This process is specialized and made by PrimeCore precisely. When sink or cooktop holes are cut according to templates, it is a few fragile stones left that have thin rails of quartz, for instance behind or in front of a sink or cooktop. Those small pieces are not as strong as it should be. In PrimeCore , we use the best methods for increasing the flexural strength of stone, especially to reinforce this thin area.

The Customers should never be standing on countertop, but it happens. To avoid such problems, our fabrication processes minimize the risk of a crack countertop.

POLISHING

After fabrication, we polish the quartz pieces. When the quartz arrives to the fabrication from our slab production facility, the face of slab is already polished. Normally the quartz face is not polished or changed at the fabricator’s workshop. The edge is need polished however.

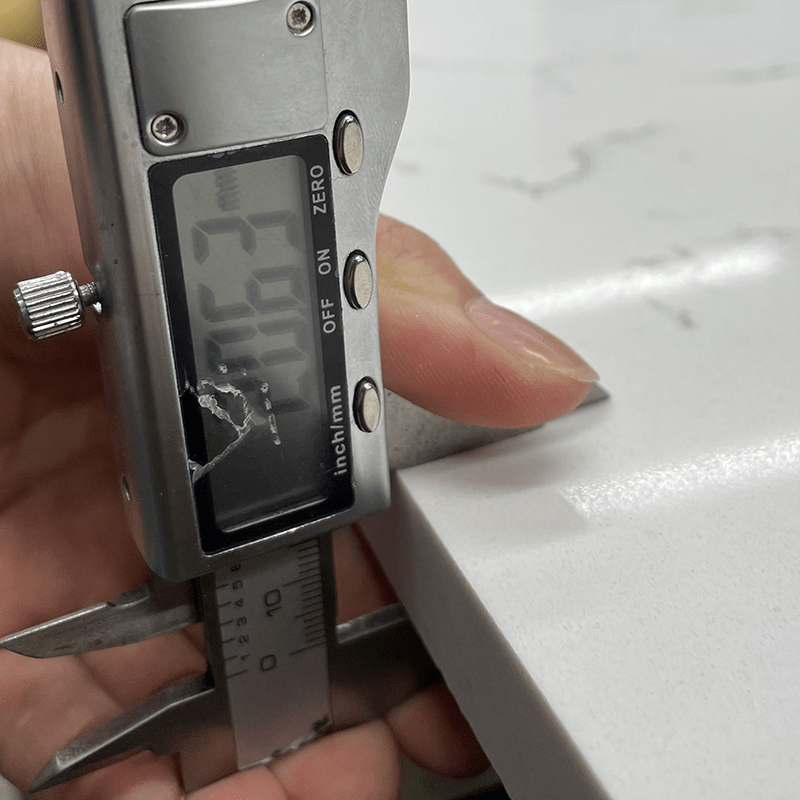

The edge is polished in 8 steps. We use diamond polishing pads of increasing grit from 46 to 2,500 to polish the edge. Beveling is made before the first polishing pad if needed. The edge polishing machine first starts with a diamond segment for easing or beveling. Then, polishing pad from 46 and 100, 200, 400, 800, 1500, ending at 2,500. The edge machine bevels and polishes at the same time, leaving the edge shaped and polished.

SEAM PHANTOM

This process is needed for the edges of the quartz ground to remove the microchipping and achieve the best seams possible. It gives the installer “a finished product” where the seam should fit nicely together, not working too much to fit it.

QUALITY CONTROL & HAND FINISHING

The last process is inspection of the countertop. The fabricator ensure that all edges are uniform around at all sides of the countertop. Then they will be checked from different angles to make sure the light is bouncing off the edges quite uniformly, and the color of the surface of the stone and the edges match perfectly. After this process, we have a finished product ready to be installed at job site.

PACKAGING

We use wooden crate for countertops. The wooden crates have all fumigation certificates and protected by approved chemicals against possible harms.

Our crates are designed for 10.000 lbs weigth. But we just load them 5.000 lbs at most.

All countertops are covered by film to avoid from scratching each other.

The crates are coated against humidity in order to protect tops during shipping.

CONTAINER LOADING

All slabs are calculated to fit appropriate crates. We plan container allocation precisely due to ensure safest and most efficient loading. We double check if unloading could be made easily and safely at the customer site.

Our Team

Our comprehensive team of professionals is designed to cater to a diverse range of clients, from subcontractors to wholesale distributors.

Ugur SACIR

Co-Founder, CEO

Ismail Ikiahirli

Co-Founder, Technical Manager

Mehmet Bakir

Logistic Chief

Bora Sacir

Sales&Marketing Chief