PrimeCore is a high-gloss, high-density, ultra-compact quartz surface. Quartz occurs naturally in clusters and, unlike granite, does not form large blocks of stone. This makes quartz stone, in its natural state, unsuitable for use as countertops or other large slab applications, and hence the need to convert quartz aggregate materials into another form, i.e. engineered stone, to make it usable for such applications.

Engineered Quartz Stone is produced by vacuum vibration compaction of an aggregate mix of quartz aggregate (grit & powder), unsaturated polyester resin, pigments (for coloring) and other chemicals that facilitate resin curing. Engineered stone slabs can be produced in:

– A wide variety of colors and patterns

– Different textures – fine or coarse, depending on how it is processed

– Special effect products: Quartz can be combined with glass and other reflective materials to create a sparkling finish. Increasingly popular in high-end applications, they combine the benefits of granite’s durability with the non-porous nature of quartz.

– Different thicknesses – 15, 20 & 30 mm depending on end use requirements

As an engineered product, consistency in appearance can be ensured to the best extent possible, except for minor batch variations.

The slabs can be produced in mono-color or multi-color, almost closer in appearance to natural stone, but with much superior physical, mechanical & chemical properties.

PrimeCore is a high-gloss, high-density, ultra-compact quartz surface. Quartz occurs naturally in clusters and, unlike granite, does not form large blocks of stone. This makes quartz stone, in its natural state, unsuitable for use as countertops or other large slab applications, and hence the need to convert quartz aggregate materials into another form, i.e. engineered stone, to make it usable for such applications.

Engineered Quartz Stone is produced by vacuum vibration compaction of an aggregate mix of quartz aggregate (grit & powder), unsaturated polyester resin, pigments (for coloring) and other chemicals that facilitate resin curing. Engineered stone slabs can be produced in:

– A wide variety of colors and patterns

– Different textures – fine or coarse, depending on how it is processed

– Special effect products: Quartz can be combined with glass and other reflective materials to create a sparkling finish. Increasingly popular in high-end applications, they combine the benefits of granite’s durability with the non-porous nature of quartz.

– Different thicknesses – 15, 20 & 30 mm depending on end use requirements

As an engineered product, consistency in appearance can be ensured to the best extent possible, except for minor batch variations. The slabs can be produced in mono-color or multi-color, almost closer in appearance to natural stone, but with much superior physical, mechanical & chemical properties.

INPUT RAW MATERIALS:

- Crushed Quartz: As the name suggests, the major ingredient is Quartz mineral which constitutes approximately 85%-92% by weight of the finished product. This quartz mineral is procured in pre-crushed condition. The quantities and sizes of the quartz grit & powder used for making slabs, vary depending on the final appearance and application of the product

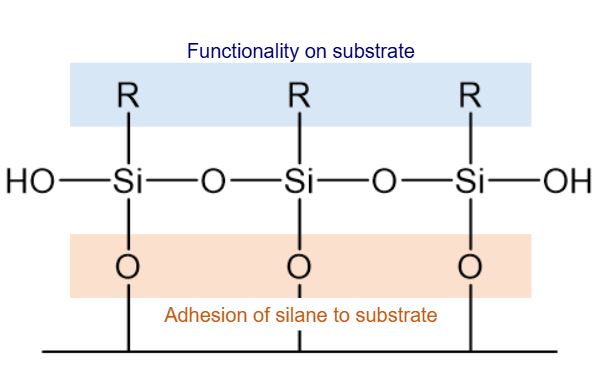

- Bonding & Curing Chemicals: Un-saturated polyester resin is used to bind the quartz aggregates and makes it rock-hard similar to the natural stone. To have a controlled reaction of resin, catalyst and accelerator chemicals are used in very small proportions approximately 1% & 0.1% of Resin respectively. In-addition, to have a good binding between resin & siliceous materials, a coupling agent called dyna-silane is used as an additive, approximately 1% of Resin by weight. All the chemicals including resin constitutes the balance i.e. 8%-15% of the total weight of the slab.

- Pigments: Inorganic & organic pigments (chemically inert) are used to induce different color shades in the product. There are whitening pigments & also color pigments.

- Miscellaneous materials: By virtue of its process, other materials such as glass, mirror, shells etc. can be used to give special effects and elegance to the finish product

- Special effect products: Quartz can be combined with glass and other reflective materials for a sparkling finish. They are increasingly popular in high-end applications combining the benefits of granite’s durability and non-porous nature of quartz.

RECEIPT & STORAGE:

Receipt and inspection of pre-crushed quartz grit & resin is a prerequisite step in the manufacturing of Quartz Surfaces. This stage involves checking the raw materials for quality and suitability. All the accepted raw materials are stored separately to prevent cross-contamination.

SILO LOADING:

The pre-crushed quartz of various granularities, are loaded in vertical storage silos to facilitate easy extraction, in the required proportions.

PIGMENT PREPARATION:

Dry pigments are prepared off line, as per the formulation and then supplied to production department based on the plan. Pigment preparation is controlled by R&D function to ensure consistency and close control on the color shades

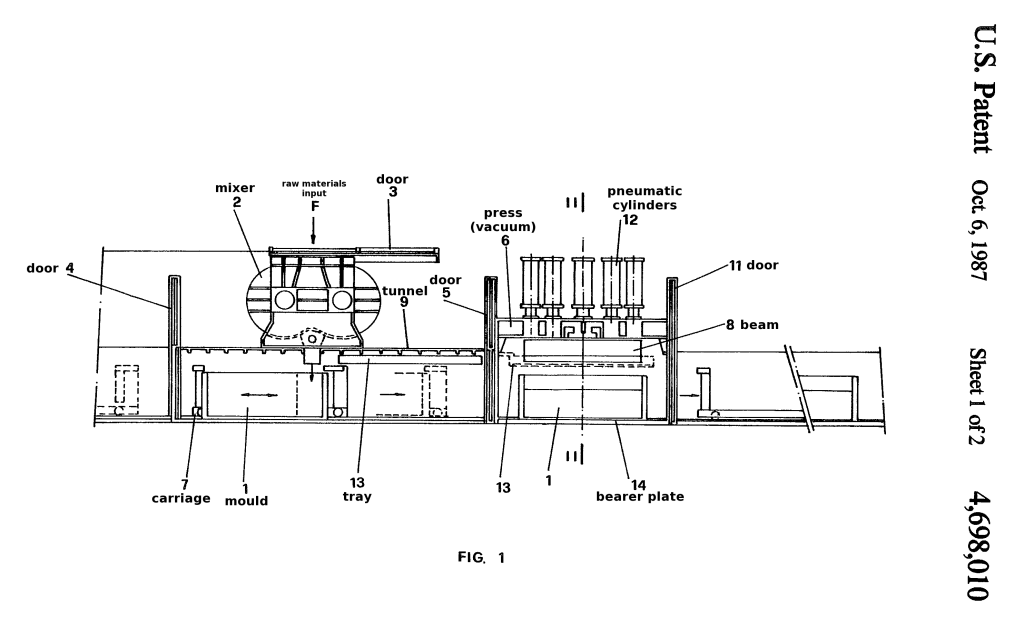

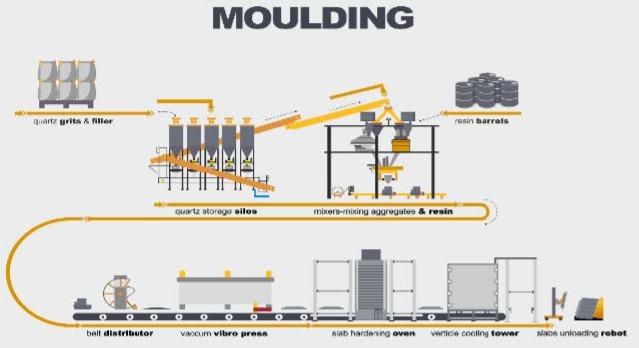

MOULDING:

Proportioning & Mixing: Different Quartz aggregates are proportioned, depending on the end design pattern, and are transferred to a mixer, where in Resin, pigments & Other chemicals are added to the aggregate mix. The aggregates are thoroughly mixed.

Blending / Lump Breaking / Homogenization: The output of each mixer is blended in Ring Mixer and passed through Lump Breakers in to a collection hopper

Distribution & Decoration: The distributor unit picks up the material from hopper and distributes the aggregate mixture uniformly to the shape of the slab. It also facilitates incorporation certain kind design patterns while distributing. The designs are through and through of the body.

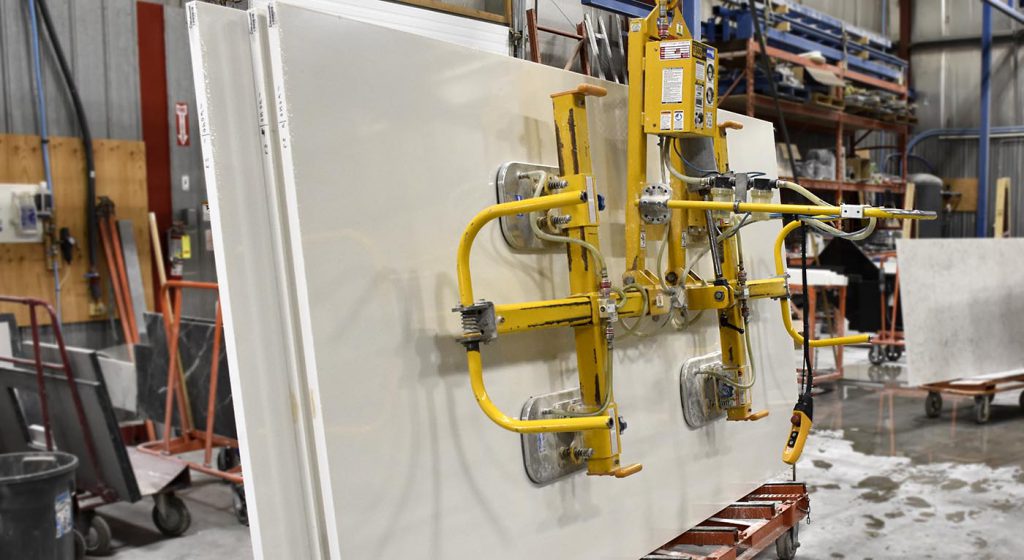

Pressing: This distributed material is subjected to a high degree of compaction, by applying mechanical pressure and vibration under vacuum conditions. This makes the slab a highly compacted one with resin as a binding agent.

Hardening / Curing: This highly compacted slab is then cured to enhance the catalysis process for an about 45 to 60 min. During this process, the resin undergoes exothermic catalytic reaction and becomes very hard.

Cooling: The cured slab from the Oven is transferred in to a vertical or horizontal cooling chamber, where in it is made to cool to room temperature.

The cooled slab becomes, a solid rock like substance, similar to granite slab. This slab is then trimmed, calibrated and polished to glossy finish or to different surface textures as per the end requirement.

POLISHING:

Polishing of quartz slabs is more or less similar to Granite polishing. The steps involved are:

Calibration: Both top and bottom surfaces are calibrated using diamond abrasives. After calibrating the first surface, the slabs are over-turned and the other face also is calibrated

Trimming & Beveling: Both long and short edges are trimmed to size and then beveled

Polishing: The slabs are made to pass under the rotating grinding spindles fitted with series of abrasive fickerts to achieve good polished surface. Normally polishing machine is equipped with multiple polishing head

The end result is the high gloss, high density Quartz slabs of dimensions 3200 x 1620 mm and 3520 x 1520 mm and 3050 x 1450 mm in 15, 20 & 30 thicknesses.

PACKING & DISPATCH:

The accepted slabs are stored on special design A Frames and are later packed in wooden crates for dispatch.

Since the slabs are brittle, these are to be kept in vertical position while during storage or during packing. Wooden crates are to be properly designed to keep the slabs vertical and also to see that the polished surface does not get damaged. Suitable care needs to be exercised, while selecting the wood quality and the wood sections, so that the crate can withstand 3 to 4 tons of loads.

Leaving an indelible mark on the landscape of tomorrow.

“Our commitment to delivering exceptional quality through sustainable practices and cutting-edge technology makes us an excellent choice for discerning importers and distributors in the competitive U.S. market..”

Ugur SACIR

CEO, PrimeCore Supply